IIoT = Automation powered by CODESYS

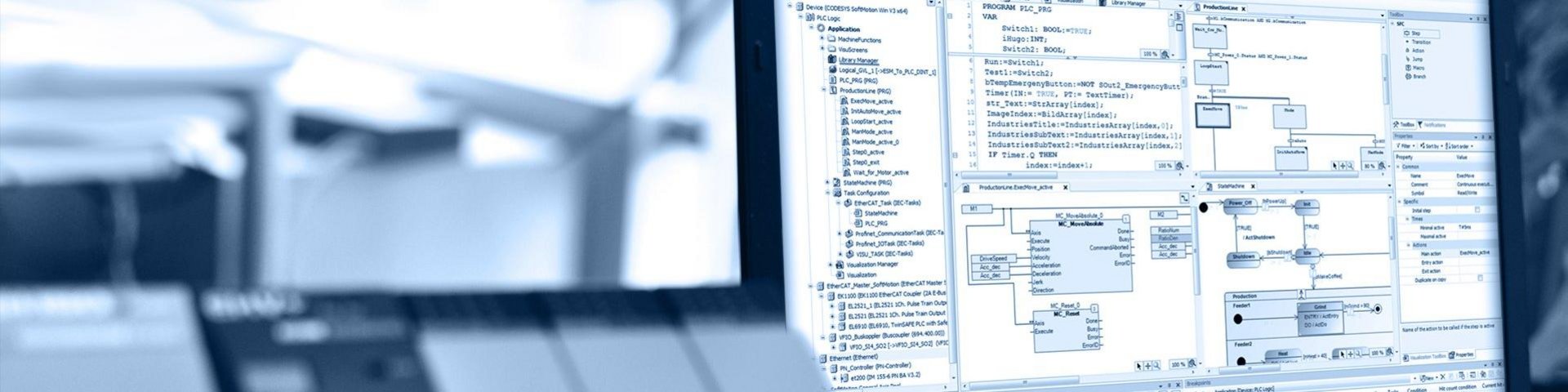

CODESYS natively contains all essential technologies and properties for applications in industry 4.0 / IIoT environments. This makes CODESYS the ideal tool for the implementation of automation solutions using IT and internet technologies. CODESYS turns a compatible controller into a powerful industrial internet device.

CODESYS makes it easy to use the latest technologies - for the immediate benefit of application programmers, machine and plant engineers, system integrators and operators. The Industry 4.0 platform CODESYS Automation Server uses web technologies to make typical tasks easier for users.