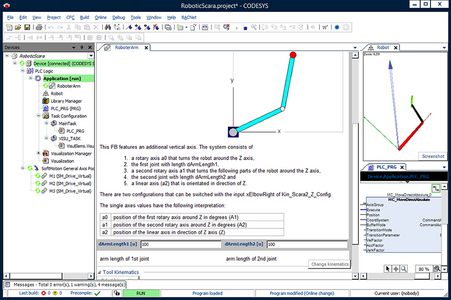

CODESYS Motion CNC Robotics

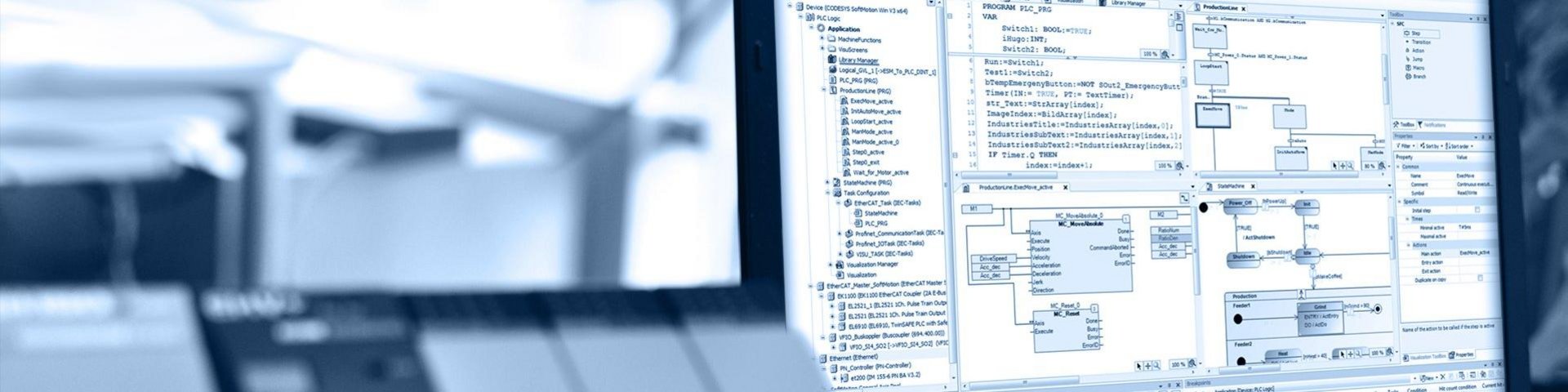

Control and Motion become one – Motion Control fully integrated in the IEC 61131-3 Development System CODESYS

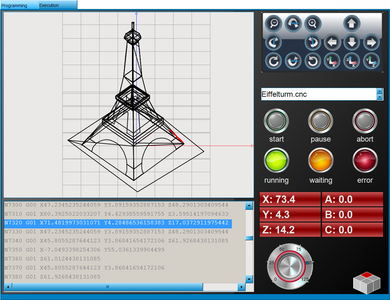

From single axis movements to multi-dimensional CNC path interpolations and complex robot applications – with CODESYS Motion CNC Robotics you can develop your motion/CNC/robot tasks without leaving your familiar logic controller development environment.

In contrast to classic motion solutions, CODESYS Motion CNC Robotics provides the required motion functionality in form of a tool kit directly integrated in the PLC development system. Using this tool kit and the language scope of the IEC, you can develop solutions for the most complex motion applications.

Available Products

- CODESYS SoftMotion: Contains the Motion Tool Kit with PLCopen POUs for master and slave movements, CAM editor and visualization templates

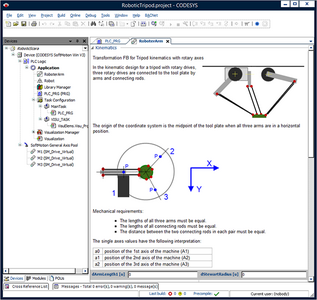

- CODESYS SoftMotionCNC+Robotics: In addition to the POUs made available in CODESYS SoftMotion, CODESYS SoftMotion CNC contains POUs for CNC functionality, different kinematic transformations with the appropriate visualization templates, PLCopen Motion Part 4 and editors for 3D CNC and the robotics axis group editor.

Typical Applications

- CNC application: CNC editor, PLCopen POUs to jog the axes, portal kinematics with step motors, teach functionality

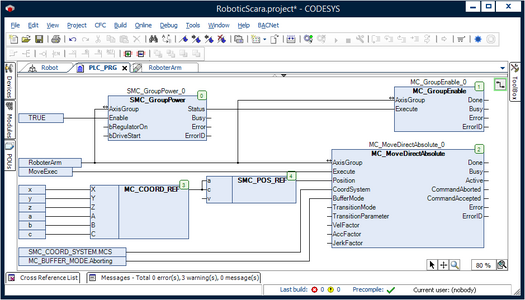

- Pick&Place-Applikation: PLCopen POUs to position (pick) and belt-synchronously place an object on a moving target, visualization templates to visualize the process. As an alternative: Use of the PLCopen POUs for “Coordinated Motion” (Part 4) with pre-configured robotic axis groups.

- Tripod Robot: Parallel kinematics (transformation), visualization template for parallel kinematics, configuration of EtherCAT® drives

- Labelling / CAM Application: CAM editor, PLCopen POUs and virtual axis used as king pin, various visualization templates, CANopen® servo drives, touch probe / latching functionality

- Injection Moulding Machine: Realized with PLCopen POUs and other SoftMotion-specific functions such as on-the-fly switching from position control to torque control

CAN/CANopen

- Bonfiglioli® iBMD

- CMZ® BD, SD, LBD

- Festo® EMCA, CMMP

- Generic CiA® 402 driver (also for multi-axis drives)

- Infranor® cd1-k, XtrapulsPac

- JAT ECOVARIO®

- KEB® F5, Stepless Technology, BD

- Metronix® ARS 2000 series

- Nanotec® PD4C

- Schneider Electric™ Lexium05, Lexium23, Lexium28, Lexium32, Lexium32i and SD-3

EtherCAT

- Beckhoff® EL2521, EL5101, EL72x1, EL703x, EL704x

- Bonfiglioli iBMD

- Bosch Rexroth® ctrlX Drive CoE

- Bosch Rexroth® IndraDrive CoE (Start-up Documentation)

- CMZ BD, LBD, SBD

- Control Techniques™ Digitax, Mentor and Unidrive

- Copley® Accelnet

- Delta® ASDA A2, A3, B3

- Delta R1-EC5621

- Festo CMMP EtherCAT

- Generic CiA 402 driver (also for multi-axis drives)

- Generic SoE driver (also for multi-axis drives)

- Hitachi® ADV series

- Infranor XtrapulsPac

- JAT ECOVARIO

- KEB F5, H6, BD

- KEBA® KeDrive D3

- Kollmorgen AKD®, AKD Servodrive, AKD-N/C, MKD-N/C, AKD2G

- Metronix ARS 2000 series

- Omron® G5

- Nidec® Unidrive M

- Panasonic® MINAS A5B, A6B, A6 MultiDrive

- Parker® compax3, SBC, PSD

- Sanyo Denki® RS2

- Schneider Electric Lexium32, Lexium32i

- Servotronix® CDHD

- Stäubli® uniVAL

- Stöber POSIDRIVE®, SD6, SI6/SC6

- WEG SCA06

- Yaskawa® Sigma7 series

- You are a system integrator or a user in the machine/plant construction sector or the like:

All you need is a controller already equipped with CODESYS SoftMotion or CODESYS SoftMotion CNC+Robotics. Millions of CODESYS-compatible single devices and over 1,000 different device types from more than 500 manufacturers offer you a large range of hardware for your automation projects. CODESYS Inside offers a selection of manufacturers that offer CODESYS-compatible devices. Or simply implement your own PC-based motion controller by installing the SoftPLC CODESYS Control RTE (under Microsoft Windows) or CODESYS Control (e.g. under Linux®). - You are a manufacturer of programmable devices:

Get the CODESYS Runtime Toolkit and implement your own customized motion control system with CODESYS SoftMotion or CODESYS SoftMotion CNC+Robotics. CODESYS SoftMotion supports the most different CPUs and operating systems. - For more information or an offer please contact our sales department under sales @codesys.com

CODESYS brochures and information material

|

CODESYS - One software. All applications. Your Automation Solution.

Version: 10/2023

|

pdf

2 MB

07.11.2023

|

|

|

CODESYS - One software. Any field of application. Your automation platform.

Version: 10/2023

|

pdf

2 MB

07.11.2023

|

|

|

Verschiedene Anbieter präsentieren CODESYS-kompatible Geräte und spannende Lösungen, die für Ihre Automatisierungsaufgaben nützlich sein können.

Version: 10/2023

|

pdf

6 MB

07.11.2023

|