Facts:

Cloud systems are indispensable today – and this is true for both the private and the commercial sector. The computing power and storage capacity of cloud architectures can be booked and used almost indefinitely. The servers are extremely highly available. In the case of commercial applications subject to a fee, prices rise with the volume of data. Are these ideal conditions for replacing high-availability control systems with cloud-based solutions? Only to a limited extent. What speaks against the use of clouds as control systems is the requirement for hard real-time behavior in industrial automation. In order to move a PLC or even a motion controller into the cloud, constant latency times in the millisecond range must be guaranteed. However, these times ultimately depend on the networks used and on the server locations - and are therefore not generally and thoroughly deterministic. Decentralized control systems are therefore indispensable, at least as a fallback scenario.

Event-based and cycle-oriented

When speaking of central, cloud-based control technology, this usually means event-based processing - which seems predestined for such systems. However, cycle-oriented application structures are state of the art today and are used successfully in hundreds of thousands of different industries. A broad base of trained personnel is available for this purpose, since almost all educational institutions, colleges, and universities mainly teach cycle-oriented project planning of machines and systems. But why not switch to event-based application structures in order to be able to use cloud-based systems? Simply because event-based structures entail significant disadvantages. Especially in large, comprehensive projects, not all events are predictable. Process errors such as production stops or wedged workpieces can lead to avalanches of events whose load and effects can hardly be anticipated. In order to process these event avalanches securely, much more computing power is required for interrupt handling and intermediate storage of data than for cyclic processing. If you want to be on the safe side, it is by no means exaggerated to use a controller that is a hundred times stronger.

IIoT is already reality

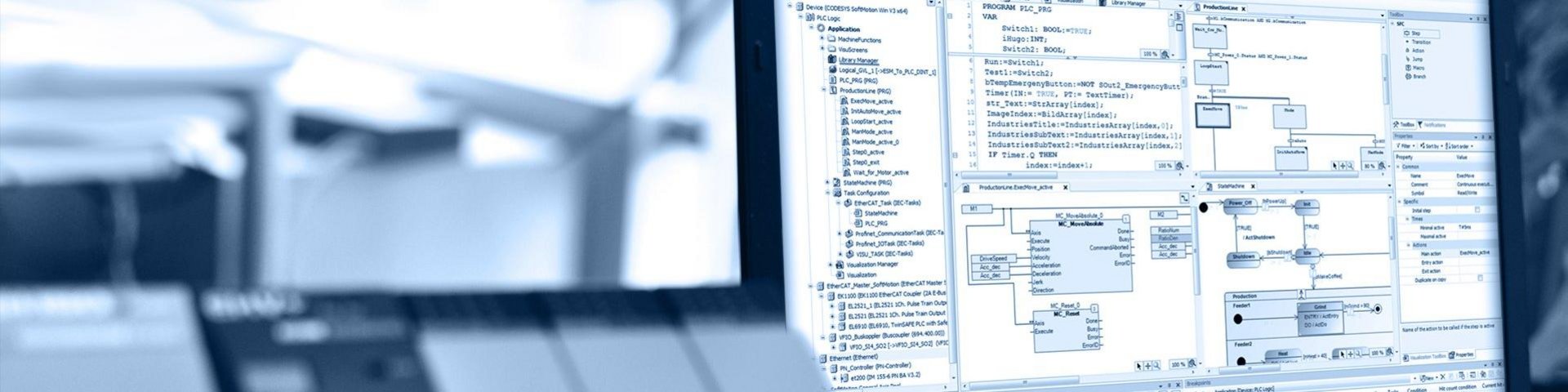

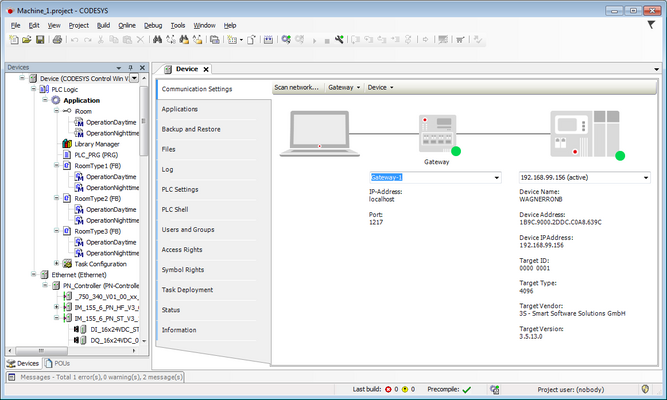

Today, almost every current controller ("thing") has an Ethernet connection and can be connected to the Internet either directly or via gateway. This makes the Industrial Internet of Things (IIoT) reality, at least to a certain extent. It does not matter which hardware platform the controller is based on. Whether classic PLCs with discrete inputs and outputs, panel controls, PC-based systems with fieldbus connection or even maker platforms such as Raspberry Pi or Beaglebone - with appropriate software protocols, e.g. in the form of library functions, these controllers can send and receive data via the Internet. Project planning tools such as the CODESYS Development System make it easy to exchange control data with the cloud or other systems. The platform independence of the tool ensures that once the application code for data exchange has been created, it can easily be processed on different devices. What is missing, however, is a consistent administration of the devices, tailored to the needs of automation specialists. The cloud is certainly the right place for this.

Prerequisite for all considerations regarding control technology in the cloud: Connection and data transmission must be secure! Repeated reports of data theft in the commercial sector are causing justified skepticism among industrial companies. Thanks to the application advantages of Internet-based systems and targeted measures for compliance with IT security, however, acceptance of these systems is increasing, despite the perceived threat. Security mechanisms that have proven successful in commercial areas are also used in industrial systems. These include encryption and signing of data and communication with X.509 certificates, hardware-based (dongle-based) encryption, and wizards to uncover vulnerabilities or potential weaknesses.

Useful scenarios

The facts explained above allow the prediction that the cloud will definitely find its place in industrial control technology. The cloud will be the "natural" storage location for production data to be collected, displayed and evaluated. Even if modern controllers have plenty of storage capacity, they would still be overwhelmed by "big data", i.e. the permanent collection of large amounts of data. Using intelligent algorithms, machine and plant operators can use such data to perform predictive maintenance, for example, because the actual machine data, compared with "taught-in" data from the normal state, can indicate anomalies and the imminent failure of components. Another scenario that has already been discussed and successfully run: "Machine Learning" or "Artificial Intelligence", the intelligent optimization of machines based on their own data. All these use cases for "big data" require large amounts of data and computer systems with unlimited performance and scalability. Such functions can help machine builders and operators to increase productivity, extend usability and functionality, and reduce downtime. Cloud protocols such as HTTPS via Web Client/REST or MQTT are used for data exchange between PLC and cloud. They can usually be used in the form of library functions directly from the control application.

Administration via the Cloud

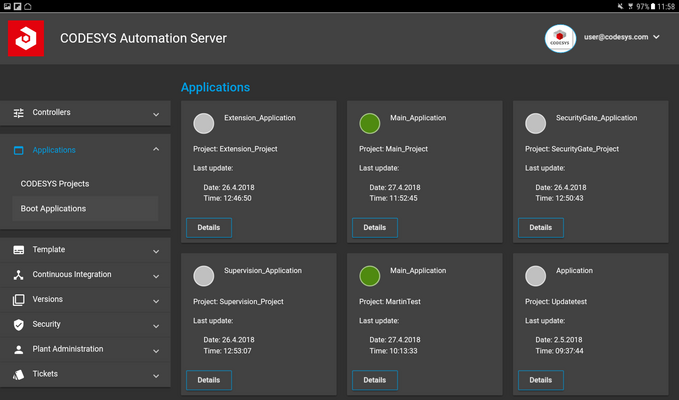

But the cloud is also the natural place for the administration of controllers and device parameters. "Go to Daimler and try to find out how many robots they have in their production line. In order to be able to do so you would actually have to count them." This is what the renowned digitalization expert Prof. Rainer Drath from the School of Engineering in Pforzheim says in an interview. "The robots cannot be found and counted via the internet today, because they are not connected. Every inkjet printer from the discount store for 80 euros offers connectivity, but most industrial components don't. This applies to all industries, oil and gas, chemicals, pharmaceuticals, etc.There is so much innovation potential here." This potential can be exploited by connecting all devices to a common server hosted in the cloud. It not only provides an overview of the controllers in the topology used in each case, but also knows their status and the software version executed. Suitable services make it easy to restore a failed controller - the server automatically creates backups and can upload them to a replacement device upon request. Another use case: A central server such as the CODESYS Automation Server can help to manage the already mentioned security certificates and to roll out user-specific settings or firmware updates. These and many other functions and services can be configured or triggered from any web browser.

Increase in quality

In today's IT software development, so-called continuous integration tools and processes are used to increase software quality. They allow for automated verification of code changes according to different criteria. The changed codes are then incorporated into the current software version. Although this procedure is still very rare in automation technology today, a significantly higher quality of PLC programs can be achieved using appropriate tools. A cloud is ideal for such tasks as it offers central control of administration and execution.

In addition, it can make sense to have certain control tasks processed in the cloud. SoftPLC systems can usually be easily installed on cloud servers, e.g. under Linux. For IEC 61131-3 tools such as the well-established CODESYS Development System, it does not matter whether the application software is loaded on a physical PLC or a virtual system and started there - the application is always accessed via the IP address of the system. As already explained, however, this only makes sense if the tasks controlled do not have to meet hard real-time requirements, if the required cycle time for deterministic processing can be guaranteed based on the boundary parameters, and if local backup systems are available.

Local Cloud in the company network

Instead of using a public cloud from Amazon Web Services or Microsoft, it can also make sense to run all the tasks addressed on a so-called edge cloud, which means locally in the corporate network. Such an edge cloud system is administered by the machine operator himself and is nothing more than a powerful PLC with appropriate memory equipment. This PLC can also serve as a gateway to public cloud systems to access external storage or performance reserves.Control technology in the cloud does make sense - especially for administrative tasks. And of course also to generate new information from large amounts of data using computationally intensive algorithms. If it comes to mixed architectures, however, cloud systems should be combined with proven, local controllers. For real-time-critical applications, the latter cannot be replaced for the time being. There is no doubt that even in ten years' time there will still be dedicated control hardware. Compared to today's systems, however, this hardware will offer significant added value through cloud connectivity.

Roland Wagner, Head of Product Marketing, CODESYS Group

SPS-Magazin, issue 10/2018.