As a family-owned company established in 1864 in Bochum, Eickhoff has developed from its beginnings as an iron foundry into a high-tech group of companies. In addition to hybrid locomotives and drive technology for wind turbines, the company specializes in special machines for the mining of raw materials. The production of its underground shearer loaders is classic special machine construction: the appropriate shearer loader can be assembled from a modular system to suit every geological requirement. These are gigantic machines used for the underground mining of coal or other raw materials with geological seams. Equipped with powerful shearing rollers, some of which are several meters in diameter, and powered by motors with an electrical power rating in the megawatt range, they mine millions of tons of coal per month – and make an important contribution to the securing of our energy supply.

Classic project planning slows innovation down

In the mechanical design of the machines, Eickhoff considered the use of combinable and exchangeable modules from early on. However, the software application of a shearer loader has until now mostly consisted of an existing monolithic project, which was adapted to the requirements of each customer. The disadvantages of this approach are known to everyone up to the top management: the commissioning of new machines or the maintenance and error correction of running machines can sometimes take weeks. This time is lacking for further development or innovations within the control application. The software developers, who were actually keen to innovate, could no longer meet the customers' ever-increasing software requirements.

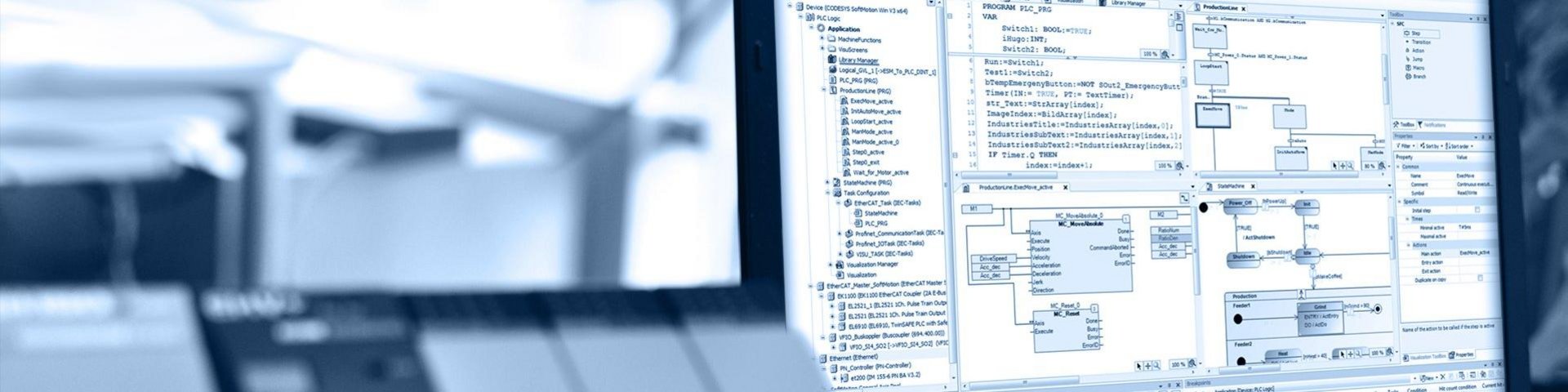

Following an in-depth analysis of the problem, a prototype approach was to lead to the decision for a company-wide solution based on the IEC 61131-3 development system CODESYS, which was already in use.

Automatic generation of IEC 61131-3 applications?

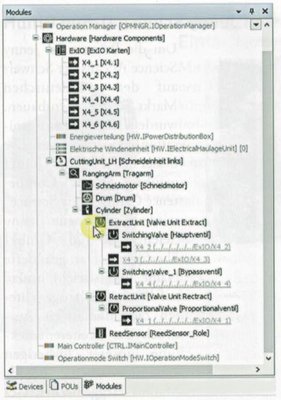

As a seamlessly integrated extension for this IEC 61131-3 tool, the CODESYS Application Composer automatically generates object-oriented control applications. To do this, the application engineer must "assemble" existing interface-based modules. This means that he configures them in a tree according to the structure of the special machine and sets the required parameters. From that, integrated generators generate application code, visualization, I/O configuration and devices – and thus the complete PLC programs.

In a two-month analysis phase, a five-man Eickhoff project team examined the current approach and developed initial approaches to the applicability of the CODESYS Application Composer. Together with the manufacturer 3S-Smart Software Solutions, a concept was created during several training courses and workshops. A subsequent six-month preliminary project to develop a prototype was to demonstrate the technical feasibility and the necessary factors and make the case to everyone involved – from the software developers to the top management – for a decision to implement the concept. "The fulfilment of these factors was crucial for the acceptance of the project and decisive for the use of the CODESYS Application Composer," says project manager Dr. Thomas Bartnitzki.

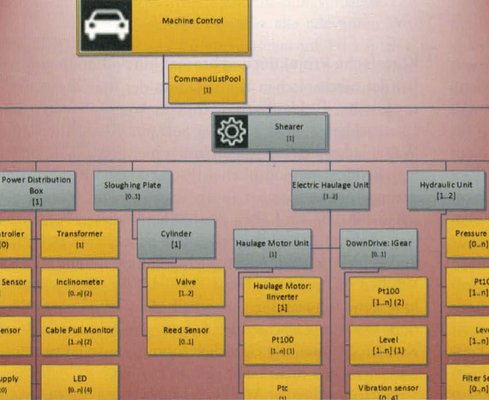

Within the scope of the feasibility study, the shearer loader was notionally dismantled into its individual parts and the hardware components were assigned to concrete, parameterizable software modules. This resulted in an object-oriented software module design that illustrates the real structure of a shearer loader. This graphical overview document provides software developers with information about the software modules that need to be implemented for the CODESYS Application Composer. It has at the same time proven to be an ideal cross-department communication medium (figure 1).

To complete the preliminary project, the application creation was demonstrated for part of the shearer loader:

- Simple configuration of the module tree

- Automatic generation of the complete control project with the generators integrated in the tool, including

- object-oriented IEC 61131-3 program code on the basis of module instances

- visualization and alarms

- persistent data ranges

- all necessary fieldbus devices including their I/O links with the modules

It was possible to download the generated application code to the controller of the shearer loader without any further adjustments - and it worked right away!

A significant reduction of the average project planning expenditure for the IEC 61131-3 application to just a few days per shearer loader - this prospect led to the Eickhoff management approving the conversion to project planning using CODESYS Application Composer.

Company-wide introduction of the new software concept

Required from the very start for the successful establishment of the tool: an executable concept for the abstraction of the modules. To this end, all aspects of the CODESYS Application Composer and its specific way of working had to be understood. Together with 3S-Smart Software Solutions, agreement was therefore reached on project-accompanying consulting for the tooling and the software architecture. As a result, a total of 140 different modules were identified, linked together by different software patterns and the appropriate module descriptions were created in a library landscape designed for the purpose. To this end, a module is described via simple textual sections. in which its metadata, interfaces, the associated visualizations, text lists, image pools and the required fieldbus devices and I/O assignments are defined. Due to Eickhoff's decision to use all available aspects in the modules, the generated code needs no further modifications.

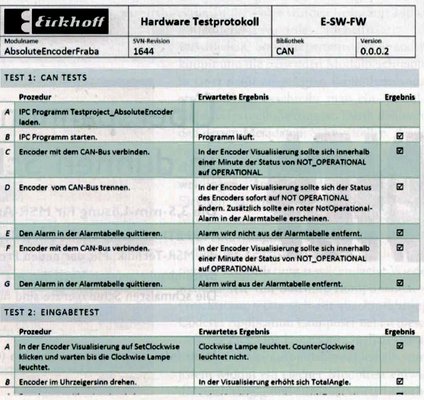

Enormous time savings due to significantly more structured project planning and simple reusability of software components – apart from this, the project team set a further goal for the introduction of the CODESYS Application Composer: constant quality of the delivered software application. For that reason, a separate module test was developed for each module that ensures the correct functionality independently and initially under laboratory conditions. Only modules that pass the tests are released for the actual application (see Figure 2).

Commissioning and operation

A technically fully approved set of modules is thus available during commissioning. With the previous way of working, the software parts used were often available and tested to a maximum of 80%. The remaining 20% were developed on site using the entire machine – as is common practice for many machine and plant manufacturers. With the help of the CODESYS Application Composer, the software developers can read the specification of the shearer loader directly from the purchase order and configure the corresponding modules for the complete shearer loader application at the workstation. A standard setup of modules and parameters is available for each model of the shearer loader and can be extended, replaced or completely removed, depending on the customer's wishes. With the view in the module tree (Figure 3), the application engineer can always keep track of all modules, their relationships to each other and the functions of the shearer loader.

The actual commissioning with roll-out of the application to the controllers and function tests will only take one day in future – as opposed to the several weeks mentioned at the start. Prior to delivery to the customer, each shearer loader undergoes a 24-hour test in a fully assembled state, in which all software and hardware functions are tested. If errors are found at this stage, that could mean a delivery delay and a lot of stress. Software developers will be spared such situations in the future. Due to the stable software design and the high code coverage, errors can be detected and corrected at an early stage. The result: huge time savings as well a reduction in the time variance for commissioning. Hence, delivery dates can now be specified much more precisely and the risk of contractual penalties is minimized.

In operation, CODESYS Application Composer programs are no different from classically created applications. Measurements showed runtimes that are comparable with the previous solutions. At the same time, the generated IEC 61131-3 code exhibits a smaller jitter and thus higher stability.

Conclusion

"I don't know of any other tool on the market that supports the object-oriented creation of a PLC application in such a professional way as the CODESYS Application Composer," Dr. Thomas Bartnitzki concludes. In his opinion, outstanding results were achieved with regard to code reusability, time savings and project overview. The prerequisites for the introduction of this tool were "time, discipline and company-wide understanding". He considers external advice to be indispensable, at least for the first project. Although the two-and-a-half-year conversion of the shearer loader project planning has not yet been completed, the Eickhoff Group has decided on the basis of the positive experience to use the CODESYS Application Composer as a company-wide software framework in order to generate synergies across the boundaries of the individual business areas.

Author: Dipl.-Ing. Roland Wagner, Head of Product Marketing, CODESYS Group

Pics: © Eickkhoff Bergbautechnik GmbH, Bochum, Germany