Background

There are several production processes that require the provision of steam, either continuously, seasonally or on demand. This ranges from the sterilization or cleaning of tanks such as in large-scale catering kitchens and hospitals, right through to food processing plants or concrete works. Steam is likewise used for the heating of greenhouse floors, as well as grass pitches in football stadiums or even for de-icing mooring ropes in the Arctic.

Challenges

The Krefeld company Certuss Dampfautomaten GmbH & Co. KG has been developing steam generators for over 50 years and uses Eaton automation technology with SmartWire-DT for the control system. Depending on the primary energy used, automatic steam generators are fired with oil, gas, electricity or with the combined oil/gas burners. Gas and oil-fired steam generators are "forced-flow once-through" boilers that are also called highspeed steam generators, since they can supply steam within five minutes. Certuss builds around 350 units a year in different performance classes and sells them around the world. When the high-speed steam generator is started, water is first of all pumped into the heating system. As soon as the set flow rate is reached, the firing is activated. The steam production is then activated according to the temperature measured. The boiler then runs up to the set pressure which can be selected as required. Previously, steam generators, particularly shell boilers, required a two-stage circuit for 50 and 100 percent. Today, Certuss produces high-speed steam generators that generate steam from the first stage, modulating from 50 to 100 percent. This virtually eliminates the need for a steam accumulator even though a permanently uniform steam supply is still ensured. In this way, precise quantities of energy can be produced that are then also taken on demand.

Solution

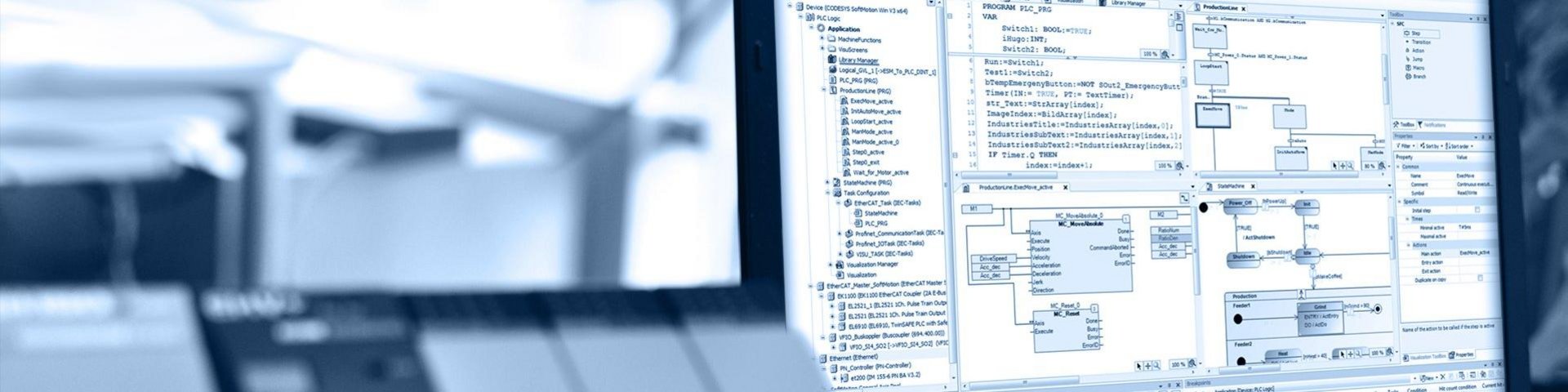

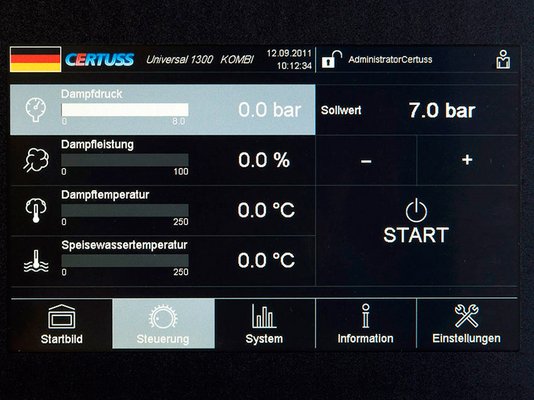

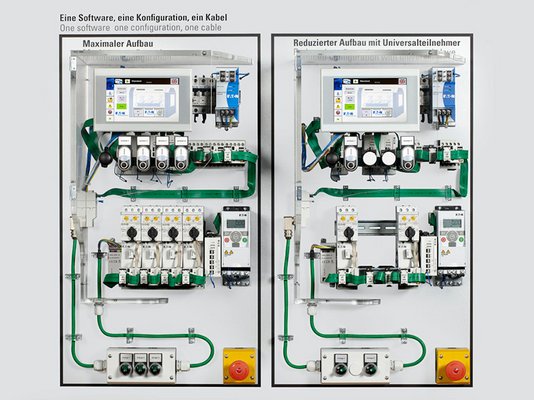

For the electrical equipment of the steam generators, Certuss chose an Eaton XV102 touch display PLC with a 7 inch wide screen, a CANopen and a SmartWire-DT interface. The touch display enables the individual elements such as pumps, blowers, fans, or additional heaters to be accessed directly. All additional parts can be configured. The pumps are actuated via PKZ motor starter combinations that are connected to SmartWire- DT. A special advantage of SmartWire-DT is the facility for system-integrated slave diagnostics: Faults are indicated in the display in plain text in 15 languages – thus enabling them to be localized and rectified quickly. An HMI/PLC controls the complete system, and the Galileo visualization software, as well as the CoDeSys programming system, is also implemented. (...)

Read the complete article (PDF 400 KB)

More Information about Eaton Electrical Sector EMEA: www.eaton.eu