Background

Every day we make use of some objects without giving them much thought, and the same goes for how they are manufactured. The production of toothbrushes, for example, requires the use of a very mature technology and a great deal of know-how. M+C Schiffer, based in Neustadt near Cologne, is an internationally recognized innovator in toothbrush production, and produces over one million toothbrushes a day in three shifts, seven days a week, on fully automated manufacturing lines.

Challenges

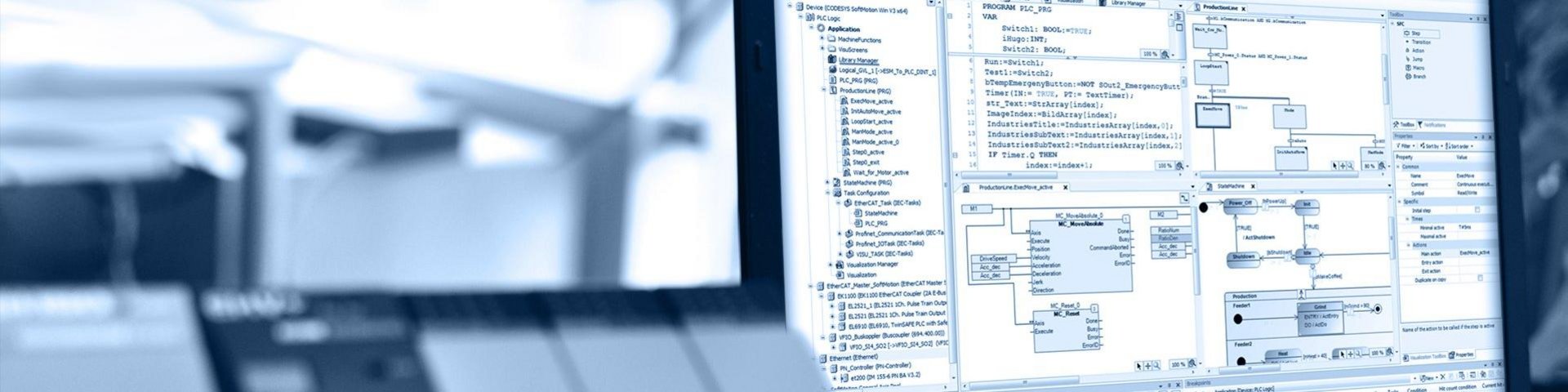

The production of toothbrushes involves a precisely coordinated chain of different processing stations: M+C Schiffer developed the complete production process themselves and integrates injection molding machines, handling systems as well as processing and packaging machines in the production chain. M+C Schiffer also develops new toothbrush models together with customers, and these include well-known companies and their brand products, such GlaxoSmithKline with Dr. Best Aquafresh and Sensodyne, Johnson&Johnson with Reach, P&G with OralB and Blend-A-Med, as well as discount stores and drugstores such as Aldi, Rewe, dm, Rossmann and Schlecker. The time synchronization of the process steps on the one hand, and the speed of individual processes on the other, present a particular challenge in the manufacturing process. Production at M+C Schiffer is fully automated in line, right through to packaging, as only a “no human touch” production meets the hygiene requirements specified. (...)

Read the complete article (PDF, 250 KB)

More Information about Eaton Electrical Sector EMEA:

www.eaton.eu

![[Translate to English:] Mehrkomponentenspritzgussmaschinen

Infrarot-Touchdisplay

Zahnbürstenmaschinen [Translate to English:] Mit Hilfe von Mehrkomponentenspritzgussmaschinen

werden je bis zu 32 Zahnbürstengrundkörper hergestellt.

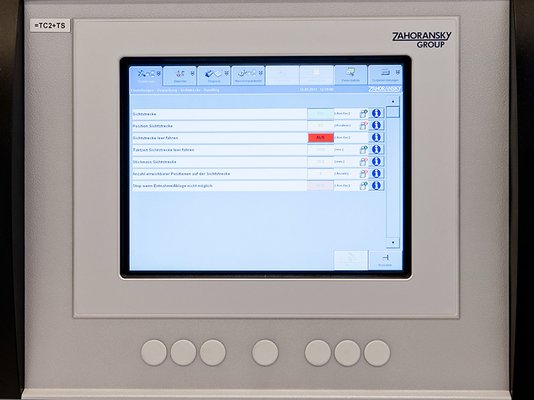

Das 15-Zoll-Touchdisplay verfügt über ein robust ausgelegtes Infrarot-Touchdisplay mit Sicherheitsglastechnik.

Durch den Automatisierungsgrad der Zahnbürstenmaschinen können Produktionsstückzahlen in Millionenhöhe erreicht werden.](/fileadmin/_processed_/8/d/csm_AG_EATON_Schiffer03_16e79c1ae7.jpg)