CODESYS Redundancy

Fail-safe control applications based on IEC 61131-3

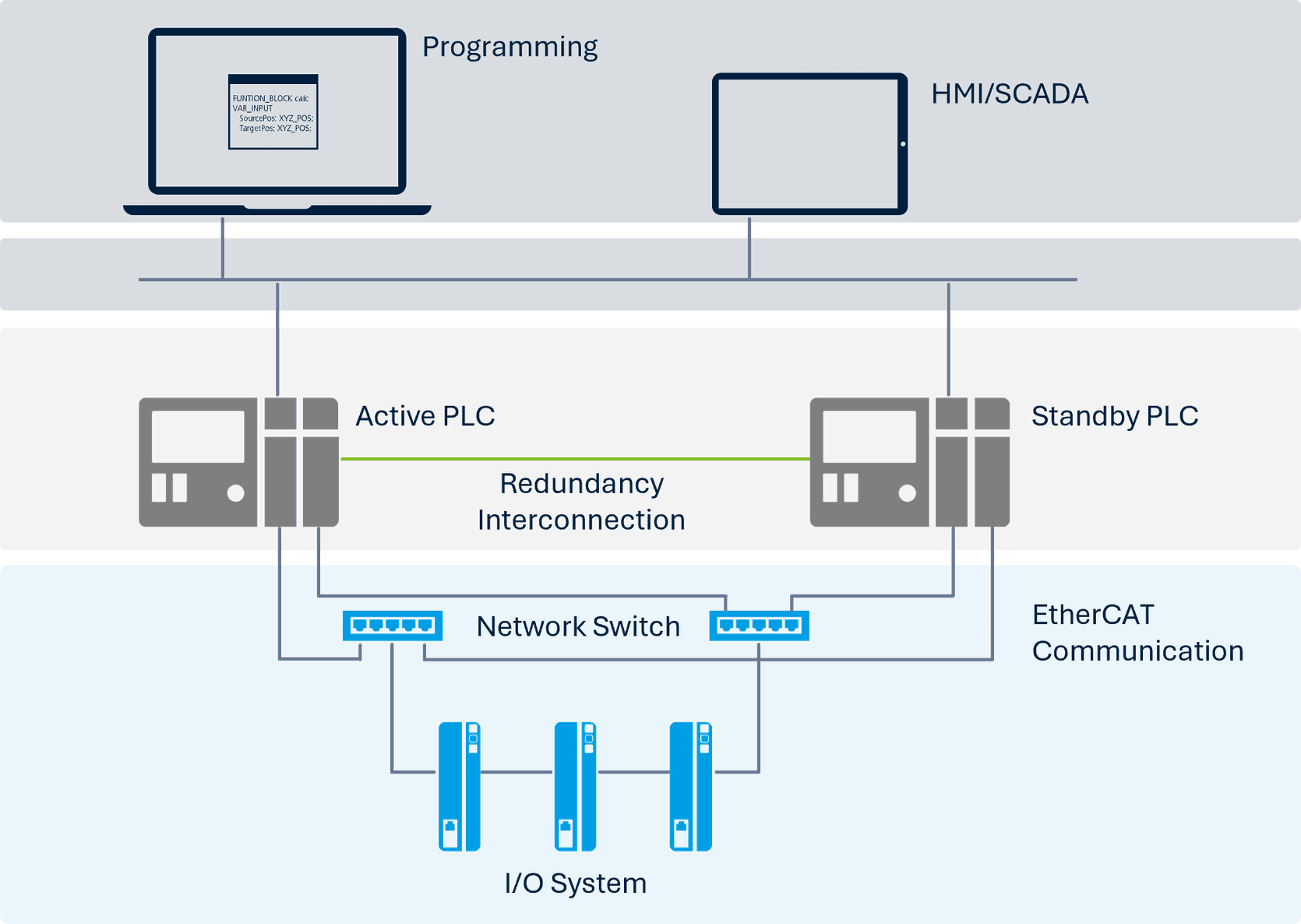

With CODESYS Redundancy, you can implement highly available control systems in which two independent controllers simultaneously execute the same application and monitor each other. This ensures maximum operational reliability and prevents production downtime.

What is CODESYS Redundancy?

CODESYS Redundancy expands the proven CODESYS Development System with functions for implementing redundant control solutions. Two PLC systems (soft PLC or hardware PLC) run in parallel and continuously exchange their status. If one controller fails, the passive controller takes over control of the system without interruption.

Limitations and requirements

- Device support: Redundancy is only available for CODESYS-compatible systems.

- Limited by the connection: A direct TCP/UDP-based interconnection between the two controllers is required. Synchronization must be performed within the cycle. Otherwise, redundancy will fail. Therefore, the amount of data that can be synchronized when using CODESYS Redundancy is limited. Other limiting factors are the speed of the hardware and the cross-connection.