Current research projects

Value creation through research

Through its own research activities and participation in publicly funded projects, the CODESYS Group is continuously advancing automation technology. The aim is to optimize resources, increase quality, and thus create measurable benefits for the industry. CODESYS is in close contact with research institutions.

Source: https://www.sdm4fzi.de/

Software-defined Manufacturing for the automotive and supplier industry (SDM4FZI) – completed on March 31, 2025

Project goal

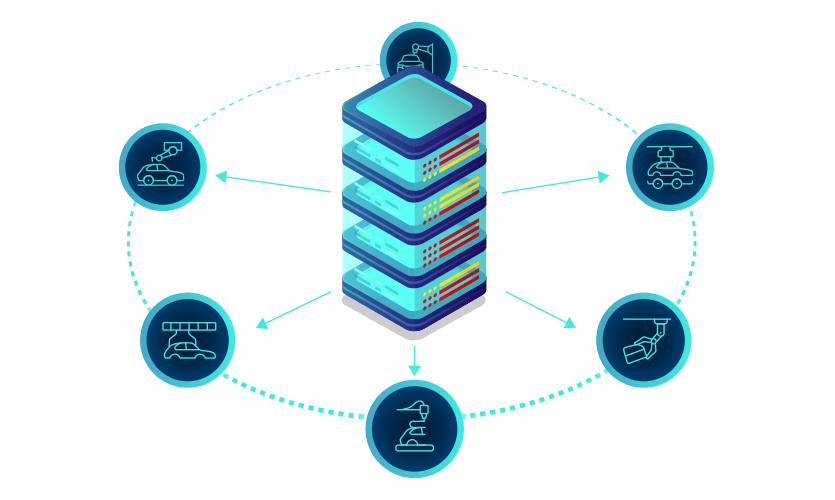

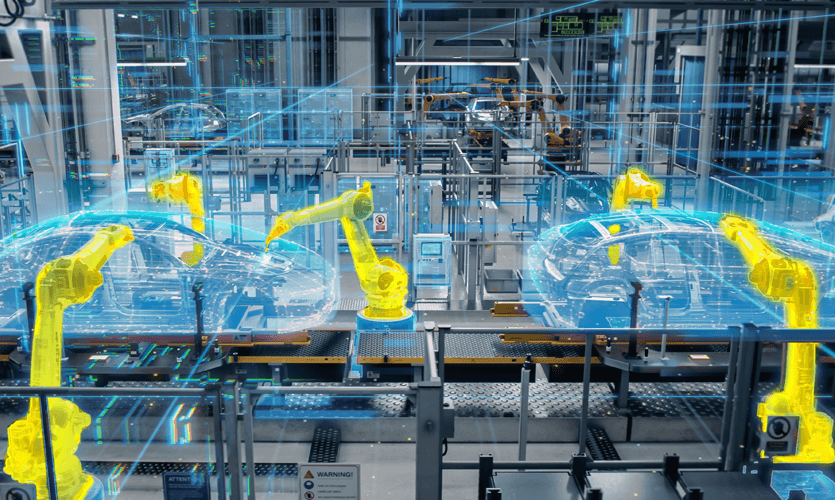

The SDM4FZI consortium (24 industrial partners + KIT + University of Stuttgart) is developing a production architecture in which manufacturing processes are described entirely through software and can be flexibly adapted thanks to digital twins. The project was funded as part of the program “Future Investments in the Automotive Industry” by the Federal Ministry for Economic Affairs and Climate Action (BMWK).

Our contribution

- Virtual PLCs and safety PLCs in freely scalable numbers, executed in the data center

- Central engineering platform (IDE) in the public cloud for cross-site project planning, management, and CI testing

This work forms the technological basis for cloud-based automation solutions and significantly reduces our customers' hardware footprint.

- Project start: 10/2021

- Robert Bosch GmbH, ABB Ltd, Trumpf SE + Co. KG, Audi AG, Karlsruher Institut für Technologie (KIT), Universität Stuttgart/Institut für Steuerungstechnik der Werkzeugmaschinen und Fertigungseinrichtungen

Product spotlight: CODESYS Simulation Interface

| Feature | Benefit |

|---|---|

Switching between real and sim I/O via OPC UA PubSub | One project, two sites – no code changes necessary |

Generic software-in-the-loop interface | Open for standard 3D simulation tools |

Compatible with any CODESYS PLC, SoftPLC, and Virtual PLC | Investment protection for existing projects |

Planned tool support in 2025: FE.screen-sim, ISG virtuos, SIMIT, Machine Expert Twin, twin (digifai) | Seamless integration into common VIB workflows |

Availability: Preview 0.9 (as of Q2 / 2025) – please contact sales(at)codesys.com

Product spotlight: virtual PLCs

CODESYS Virtual Control SL

The virtual PLC runtime CODESYS Virtual Control SL can be flexibly installed on a container or virtualization platform – scalable and without hardware binding.

Key features & benefits:

- IEC 61131-3 compatible, programmed in the familiar IDE environment

- Any number of instances per host – ideal for modular production

- Fewer control cabinets, less wiring thanks to Industrial Ethernet I/O

- Central orchestration via Linux container, Podman/Docker

CODESYS Virtual Safe Control SL

With CODESYS Virtual Safe Control SL, we are offering the first hardware-independent, SIL 3-certified safety solution – in accordance with IEC 61508 and tested by TÜV SÜD. Two software channels ensure compliant process applications – without the need for dual-channel hardware (“Diversified Encoding”).

Key features & benefits:

- Full SIL3 safety on standard x86 platform

- Real-time container solutions (Docker/Podman)

- Dual-channel execution in a single process

- Replacement for physical safety PLCs thanks to certified technology