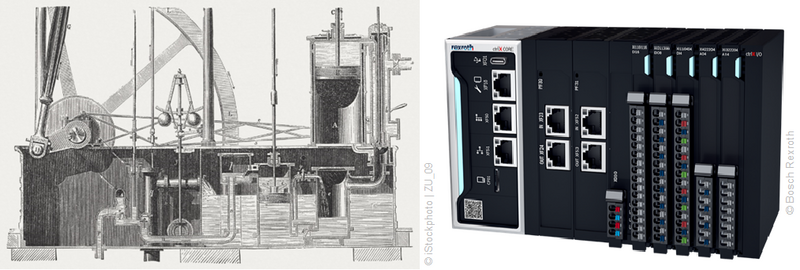

Back in the days of industrialization, purely mechanical controls, mostly powered by steam engines, made mechanical engineering important. The rapidly increasing complexity of the mechanics and the high material costs are the reason why first-generation controls have almost disappeared.

The introduction of electrical engineering resulted in new possibilities for control 2.0, especially through electromechanical components such as electric motors and relays. Individual units could be switched remotely and "control programs" could be hard-wired. However, the high wiring complexity resulted in difficult maintenance and change processes and required meticulous documentation.

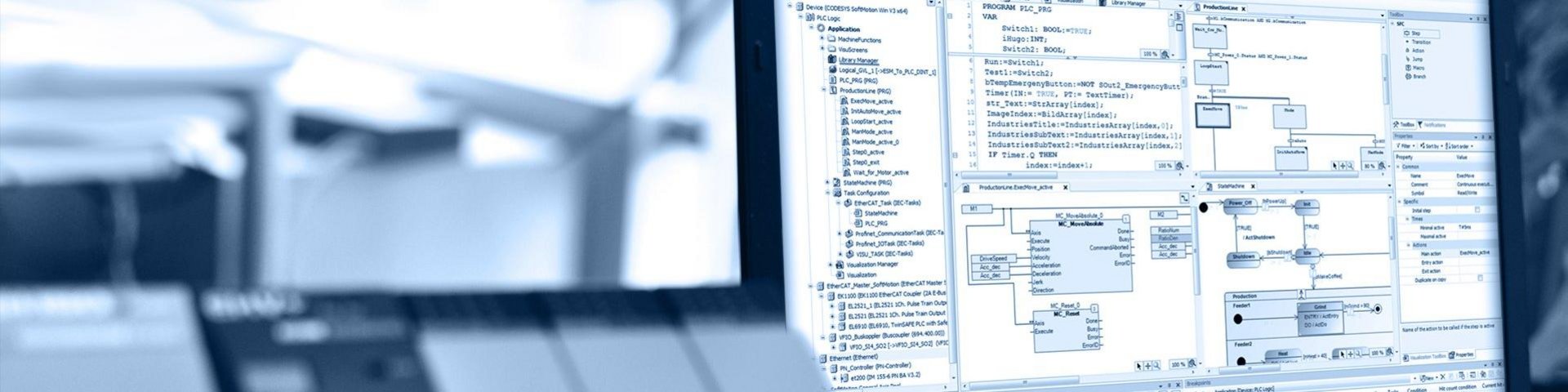

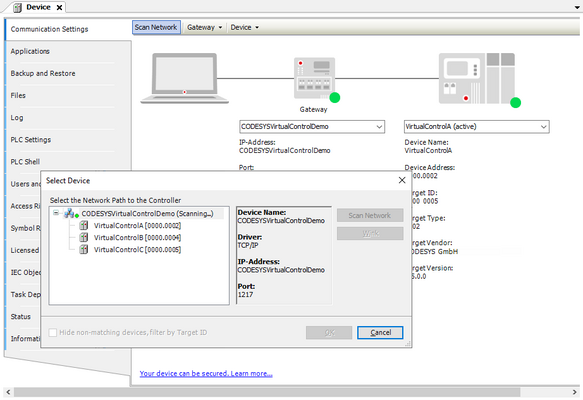

Electronics and, in particular, programmable processors paved the way for controls such as those still in common use today. The system memory of the third-generation controller is no longer hard-wired, but can be flexibly changed. This free programmability of the control led to the birth of the PLC as we still know it today. Applications can be created in PC-based programming tools such as the CODESYS Development System and loaded onto the device. When the controller is started, the stored application is executed immediately and usually runs 24/7 for decades.

Read the full article in the openautomation issue 3/23, p. 37-40 »

This article is only available in German language.

Author: Domenik Vögel, Product Marketing, CODESYS GmbH