Virtualization technology has been extensively applied in IT systems. Several aspects ranging from server, storage, applications, desktops, to operating systems and more have been virtualized.

Server virtualization is the most common use of virtualization. It involves partitioning a physical server into several smaller virtual servers. Each of these virtual servers can run their own operating system and applications, making it seem as though they are individual machines. This helps to optimize resources and reduce costs. Storage virtualization involves pooling physical storage from multiple network storage devices into a single storage device that is managed from a central console.

This helps in backup and archiving, improving efficiency and speed. Similarly, application virtualization allows running of applications in a self-contained virtual environment without the need for dedicated host computers. Desktop virtualization involves hosting a desktop operating system within a virtual machine that runs on a server. This means that the server does all the processing, and the users just need a small device (called thin or zero-clients) to connect to the server. This reduces the hardware requirements for the users and increases data security.

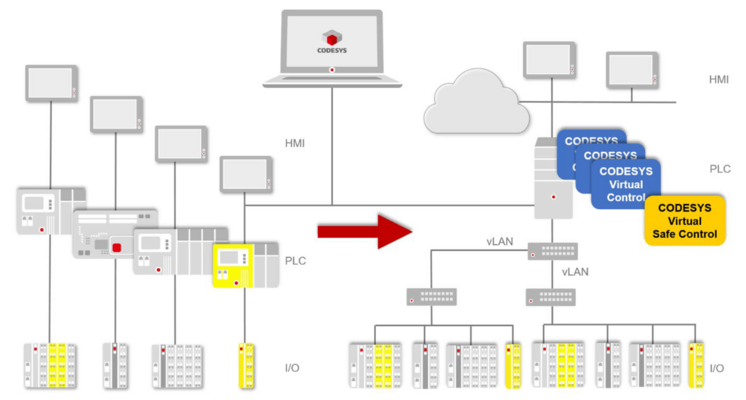

Virtualization technology has dramatically changed the way IT resources are used, and services are delivered, enhancing efficiency, flexibility, and scalability. However, the benefits of virtualization have yet to benefit industrial operations in any significant way. Industrial Automation and Control Systems (IACS) hardware resources in these environments continue to exist as discrete resources. With digitization, the number of such hardware resources has risen rapidly and so has the time and expense of monitoring, updating, and troubleshooting, which could require extended downtimes and result in productivity losses.

In this article, we will describe the benefits manufacturers can expect to see by virtualizing their IACS systems, what is holding them back, and the solutions that can help them get there.

Read full article at iebmedia.com »

Authors: Vivek Bhargava, Product Marketing Manager at Cisco, and Roland Wagner, Head of Product Marketing at CODESYS